CVD Diamond Over 34 Carats Examined in GIA’s Hong Kong Laboratory

May 3, 2023

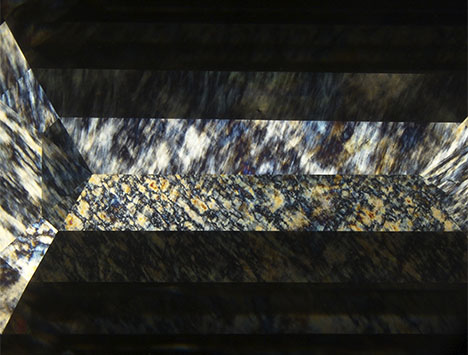

Chemical vapor deposition (CVD) growth technology has advanced significantly over the last two decades. In this study, we report on the largest CVD gem diamond GIA has encountered, recently tested in the Hong Kong laboratory. This emerald-cut diamond weighed 34.59 ct, measuring 24.94 × 13.95 × 9.39 mm (figure 1), produced by Ethereal Green Diamond in India. It had G color and VS2 clarity. Small black graphite inclusions were found. Some stood alone inside the body, while others formed clusters of clouds located between growth layers. Microscopic observation showed a weak oily or wavy graining looking through the table facet, a feature sometimes seen in CVD gem diamonds. It tends to appear more prominent in CVD diamonds with high amounts of strain and a strong birefringence pattern when viewed through crossed polarizers (figure 2).

Infrared absorption spectroscopy revealed no absorption related to nitrogen, which is consistent with type IIa diamond. However, a weak absorption related to boron (an absorption peak at ~2800 cm–1) was detected, corresponding to around 2 ppb of boron impurity. This trace amount of boron was very likely incorporated as contamination during diamond growth. There are different opinions on whether this trace contamination should be considered in diamond classification. Photoluminescence (PL) spectroscopy was performed at liquid nitrogen temperature (–196°C) with several laser excitations (figure 3). In addition to strong emissions from NV0 and NV– centers at 575 nm and 637 nm, respectively, moderately strong doublet emissions from SiV– at 736.6 and 736.9 nm were recorded. A weak emission at 946.4 nm, possibly from the SiV0 defect, was also observed. Other important emission features included a strong emission from the H3 defect at 503.2 nm and a weak emission band with peaks at 566.0, 566.7, and 567.7 nm. Emissions at 596/597 and 467.6 nm, which are common in as-grown CVD diamonds, were reduced by high-temperature treatment. These observations and spectroscopic features confirmed that this CVD diamond was annealed under high pressure and high temperature (HPHT) to improve its color appearance. In contrast, no post-growth color treatment was applied to the 16.41 ct CVD lab-grown diamond tested a year earlier in the New York laboratory (W. Wang et al., “New record size for CVD laboratory-grown diamond,” GIA Research News, January 27, 2022).

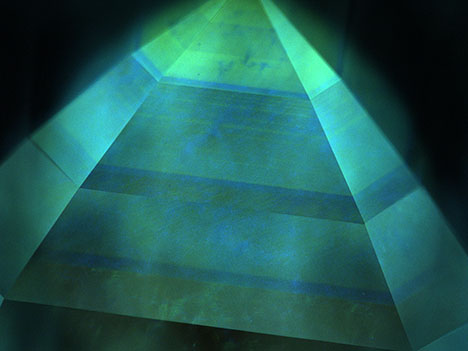

DiamondView fluorescence imaging showed green and blue colors with a banded pattern. Typical CVD growth striations were clearly visible (figure 4). Green fluorescence was from the H3 defect, produced during HPHT annealing. This banded structure revealed at least eight growth steps to achieve sufficient depth for this large diamond. Additionally, strong blue phosphorescence with similar banding was detected in the DiamondView.

This very large CVD diamond represents a milestone in CVD growth. Mined diamonds with similar size and quality are very rare. We will continue monitoring developments in gem diamond growth technology to ensure all diamonds are properly identified in GIA laboratories.

Ka Wing Tam is a senior staff gemologist, and Terry “Ping Yu” Poon is manager of diamond identification, at GIA in Hong Kong.