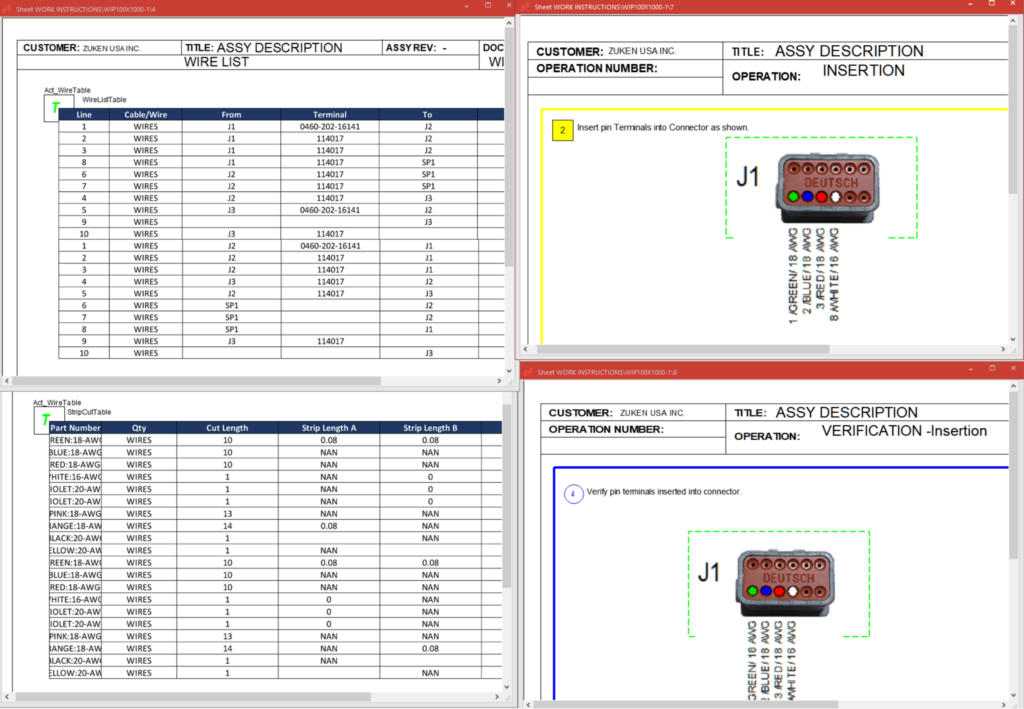

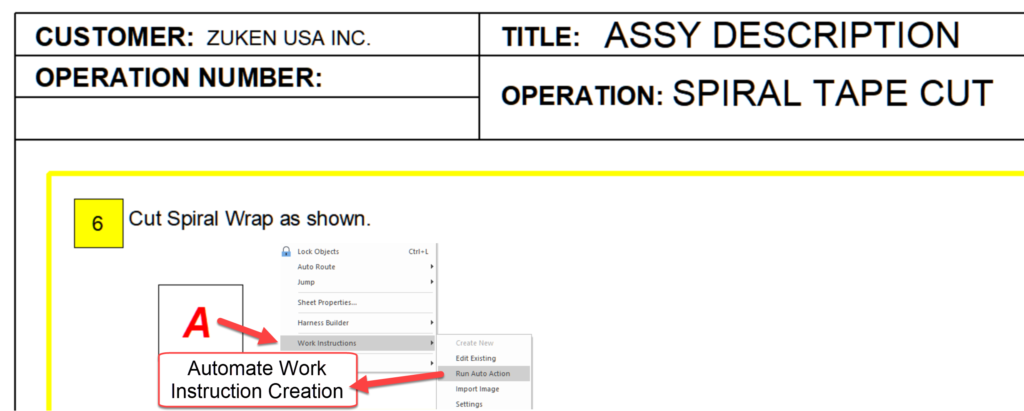

Work Instructions Assistant

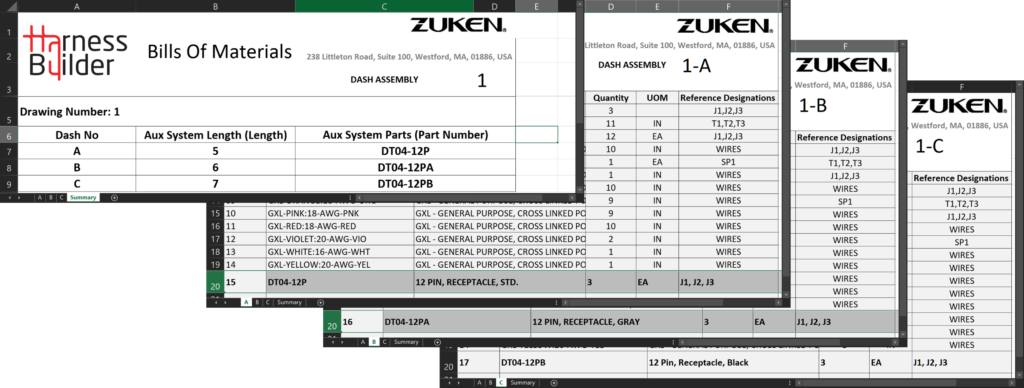

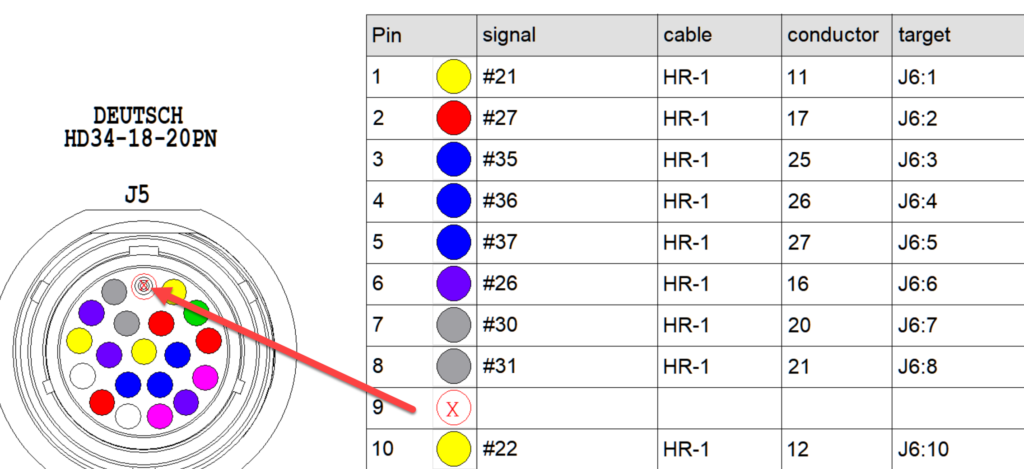

Wire harness work instructions are a customized mix of standards, best practices, testing routines, and assembly procedures to facilitate an efficient manufacturing process. Creating and managing work instructions is typically a time-consuming, manual, and error-prone process. Harness Builder for E3.series introduces an assistant to augment the work instruction creation process and automate time-consuming tasks.