Decentralized fuel-cell systems will make the internet more sustainable

Global demand for electricity continues to grow unabated. At the same time, humanity is facing a mammoth challenge in the shape of climate change. What is urgently required, therefore, are technologies for tomorrow that are compatible with today’s industrial landscape. In a pilot project, Deutsche Telekom is now trialing two stationary solid oxide fuel-cell (SOFC) systems from Bosch. These can be used to generate — efficiently, sustainably and in a decentralized way — the electricity required to power, for example, the operating centers for network systems.

The internet: a major energy consumer

Surfing, streaming, hanging out on social media — for billions of people around the world, the internet has become a fixture of everyday life. If the internet were a country, it would have come sixth in a 2019 ranking of the world’s largest energy consumers by state, according to a study by think tank The Shift Project. In a bid to become more sustainable, many internet providers are therefore shifting to electricity from renewable sources such as wind and solar. Yet both of these depend on the weather and are, as such, subject to variation. “For a telecommunications company, it’s vital to have a stable source of power. We can’t afford an outage for even a second,” says Bernd Schulte-Sprenger, managing director of Power and Air Condition Solution Management GmbH (PASM), a Deutsche Telekom subsidiary. His 140-strong workforce ensures that the parent’s “core sites” — the centers used to operate network systems — receive a constant supply of power and are therefore able to provide the company’s 48.5 million mobile customers with continuous mobile and internet services.

Hydrogen as a future source of power

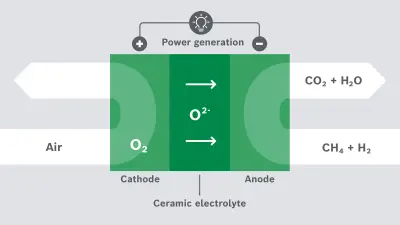

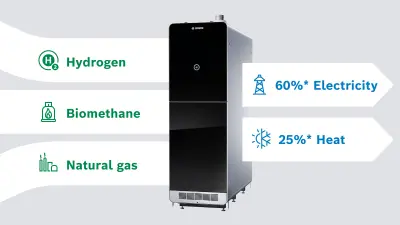

In its search for new forms of power supply, PASM is now trialing a pioneering technology at a Deutsche Telekom core site in Berlin. Here, two stationary solid oxide fuel-cell systems from Bosch were installed in February 2022. They utilize an electrochemical process to generate electrical energy from natural gas or biomethane, optionally with an admixture of hydrogen. This reaction also produces heat. When, in the future, an SOFC is fueled with green hydrogen (i.e., hydrogen produced with electricity generated from renewable energy), the power and heat produced will be completely carbon free.

Thermal energy from the reaction can be used for heating or cooling

The futuristic-looking SOFC unit houses several hundred fuel cells. These are piled into stacks, which constitute the engine of the electrochemical process. Each SOFC unit generates around ten kilowatts (kW) of electricity and around 3 kW of heat. Over the course of a year, this amounts to some 80,000 kilowatt-hours (kWh) of electricity — enough to cover the annual power needs of 20 or more four-person households. This process also produces thermal energy, which can be utilized either to heat buildings or to produce — by means of an absorption chiller — chilled water with which to cool servers.

Highly efficient and fuel-flexible

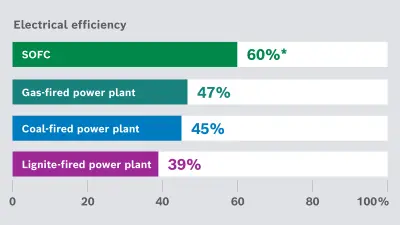

The fuel cells achieve an electrical efficiency of 60 percent. By way of comparison, a lignite-fired power plant achieves, on average, an electrical efficiency of around 40 percent, a coal-fired or gas-fired power plant around 45 percent. If the thermal energy produced by an SOFC unit is also used, this can boost overall efficiency to over 85 percent.

Furthermore, SOFC systems are very versatile when it comes to the choice of energy carrier. In the Berlin pilot project, PASM is currently using natural gas, as there is no local hydrogen infrastructure in place. In the long term, however, the company intends to switch the two pilot units to a more sustainable energy carrier. Even when running on natural gas, the SOFC is considerably more environmentally friendly than some other forms of power generation: carbon emissions are around two-thirds lower than coal-fired generation in Germany, and virtually no nitrogen oxide or particulate emissions are produced. In the future, when an SOFC is run exclusively on sustainably produced hydrogen, carbon emissions will be completely eliminated.

How does power generation work in a solid oxide fuel cell?

Avoiding grid losses

This is by no means Deutsche Telekom’s first foray into the field of sustainable power. Indeed, its several hundred core sites in Germany already operate exclusively on renewable energy. Furthermore, the company has a stake in a number of wind and solar parks. Yet Deutsche Telekom plans to go the extra mile here — and innovations like the SOFC could well provide the key. When electricity is transmitted via cable and the overhead power lines of the public grid, there are inevitably some losses. However, by using decentralized fuel-cell systems from Bosch, PASM can generate electricity precisely where it’s needed. “SOFC technology enables us to eliminate grid losses,” Schulte-Sprenger explains. “And by using the heat that is also generated, we can boost overall energy efficiency at individual locations.” What’s more, by generating its own power, Deutsche Telekom also avoids having to pay grid fees, thereby reducing its costs.

> 85 percent

overall efficiency can be achieved when using both the power and heat generated by a decentralized fuel-cell system

A digital twin for each SOFC unit

The SOFC unit is also a game changer when it comes to digital connectivity. From square one, it has been designed as an IoT device to be hooked up to the cloud. Over the entire life cycle of a stationary fuel-cell system, data is collected and then semantically linked to create a virtual image — a digital twin — that enables real-time monitoring of each SOFC unit and provides vital information to service and maintenance operatives. In addition, data from all connected units can be analyzed by means of AI, thereby enabling further enhancements to efficiency, product development, and manufacturing. Similarly, it will be possible to incorporate decentralized fuel-cell systems into customers’ own ecosystems — including energy and building management platforms. Work is also underway on augmented and virtual reality applications that will provide enhanced remote diagnosis and maintenance functionality. In other words, as well as collecting data for the purpose of continuous product improvement, a digital twin also delivers direct benefits for SOFC operators.

Big potential for the future

Decentralized fuel-cell systems deliver sustainable energy that is locally generated by a technology that offers the benefits of digital connectivity. “Such innovations point the way forward, both for us as a company and for society as a whole,” Schulte-Sprenger explains. “And, in Bosch, we have a valuable partner who will continue to develop fuel-cell technology over the long term and thereby help ensure the security of IT and telecommunications systems.” At present, the two SOFC units at the core site in Berlin provide only a fraction of the energy required there. “But, after a successful pilot phase, we can readily imagine installing SOFC systems as a key technology at our core sites,” Schulte-Sprenger adds. “Ideally, they would run on green hydrogen.” This would mark another important step toward placing the internet on a sustainable footing. With mass production of the stationary fuel cell system to be ramped up in 2024, Bosch will be well placed to meet this demand.